Author:Yang, L., Zhao, Y., Peng, R., & Ma, X.

Abstract

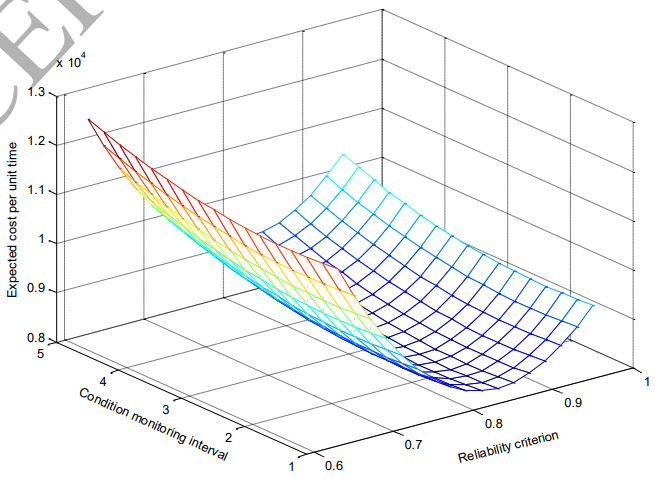

Competing failures are extensively observed in complex industrial systems, which may result in tremendous economic losses and safety hazards. In this article, we study a system subject to two typical failure modes, degradation-based failure and sudden failure. The system is operating under a random environment where external shocks arrive according to a Poisson process. The impact of shock damage on system failure is two-fold: (a) increase the hazard rate of sudden failure; (b) cause abrupt degradation increment. The system is preventively replaced when its age attains a pre-determined threshold (age-based replacement), and undergoes a finite number of condition monitoring (CM) before this replacement. At a CM, the control limit of preventive replacement varies with the number of CM and is determined by a reliability criterion. The objective of this paper is to jointly optimize the replacement interval, monitoring interval and reliability criterion such that the expected cost per unit time is minimized. A case study on oil pipeline is provided to illustrate the applicability of the maintenance strategy.

Keywords:Maintenance; Competing failures; Random environment; Non-constant control limit